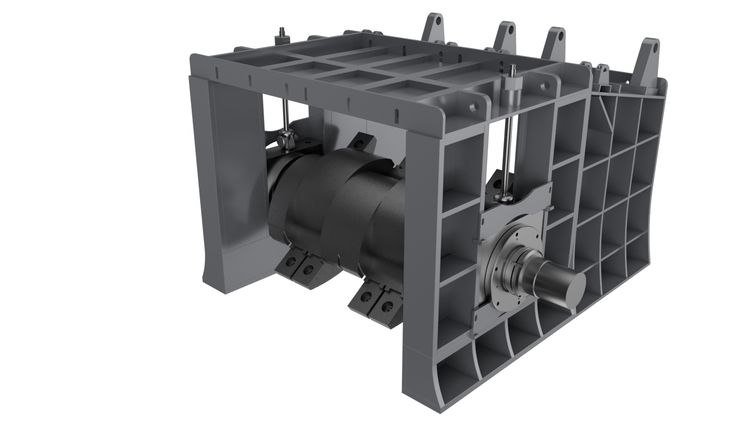

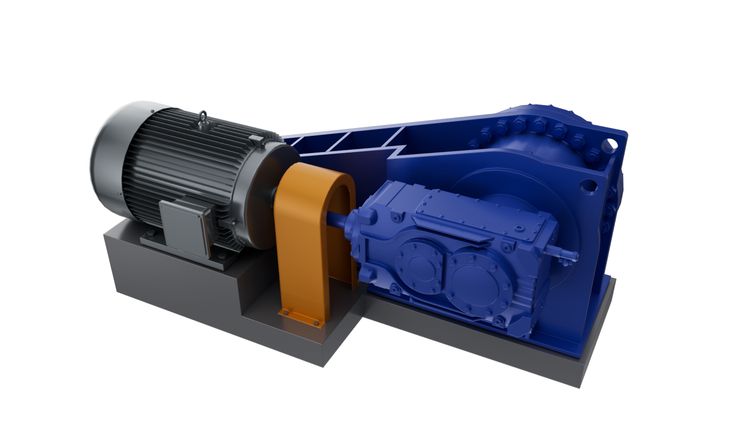

The Feeder Breaker is a continuous roller crushing equipment that integrates feeding, crushing and screening functions. It is the connection between the mining system and the material handling system, which utilizes chain feeders and horizontal crushing rollers to continuously feed and crush the mined materials.

Feeder Breaker consists of chain/apron feeder and crushing unit, which realizes the combination of feeding and crushing functions. The materials are directly unloaded into the hopper by dump trucks, or unloaded into the hopper by bulldozers or loaders, and then When the drive device of feeder starts to run, the drive sprocket drives the chain to move horizontally in the conveying box and drags the material forward at the same time.

When the chain and the material through the rotary teeth roller in the crushing box, because the large material cannot pass through the specific space between the teeth roller and the base plate, the large material will be knocked, squeezed and stretched by rotating toothed rollers until broken into small materials which are allowed to pass through.

In general the feeder breaker can crush the large materials(800mm-2000mm) into medium sizes(200mm-400mm).

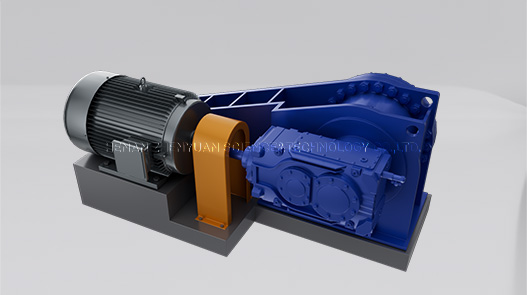

ROLL CRUSHER

Our feeder breaker can be equipped with two forms of crusher according to the different needs of our customers.

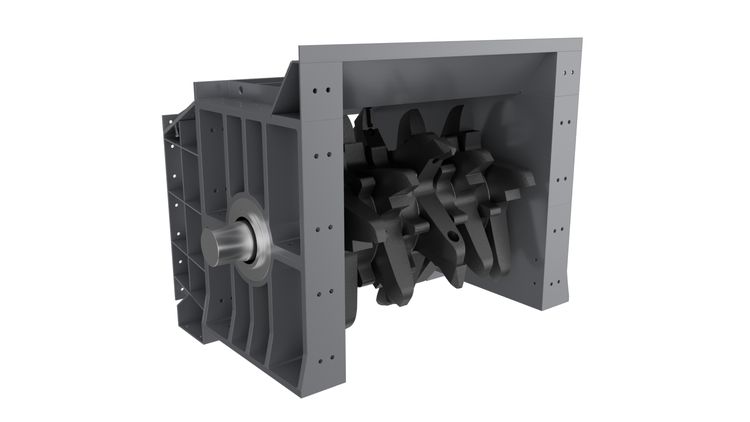

Hammer Crusher

The hammer crushing teeth head are fixed by the way of movable teeth head, which is easy to replace and reduce loss. The crushing method using a breaker hammer has a significant effect on the presence of ultra-large pieces of materials in open-pit mines.

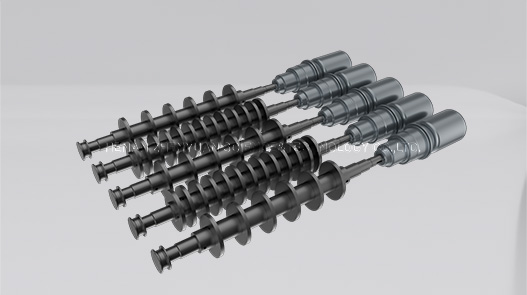

Teeth Roll Crusher

The crushing teeth are made of special formula materials after precision casting and heat treatment, with high strength, wear resistance and impact resistance.

The crushing teeth adopt special installation technology and design structure: adopt high frequency heating assembly, the structure is firm, reliable and durable. Unique and novel tooth design structure, deep spiral distribution, strong biting capacity, high production efficiency.

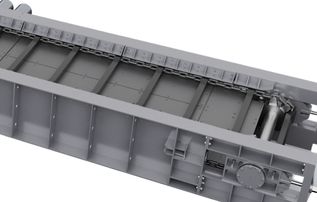

CHAIN SCRAPER FEEDER

Our feeder breakers are also equipped with the following parts to ensure smooth operation of transport functions:

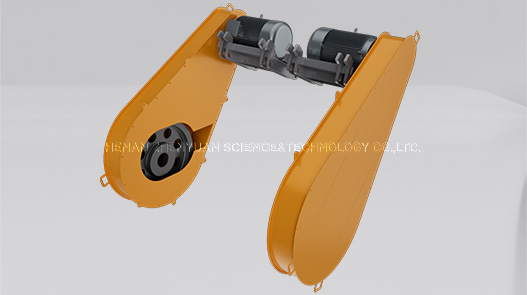

Drive Device

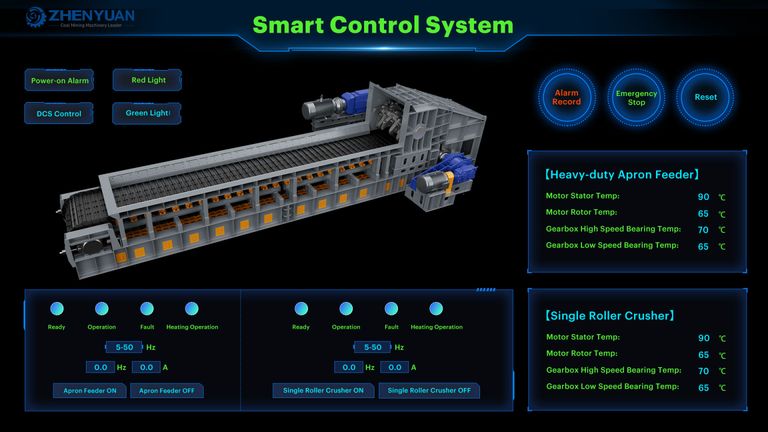

Our drive system utilizes an AC variable frequency drive system that integrates software with electronic and mechanical systems to provide precise feeder speed control and overload protection.

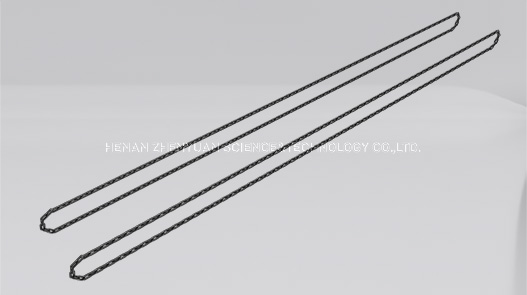

Chain & Scraper

The hauling chain adopts a high strength mining circular chain connected by connecting rings, with a long service life and easy change. The conveyor scraper is made of alloy steel, which has the advantages of high strength, high tensile strength, compact structure, withstands strong impact, installs easily and others.

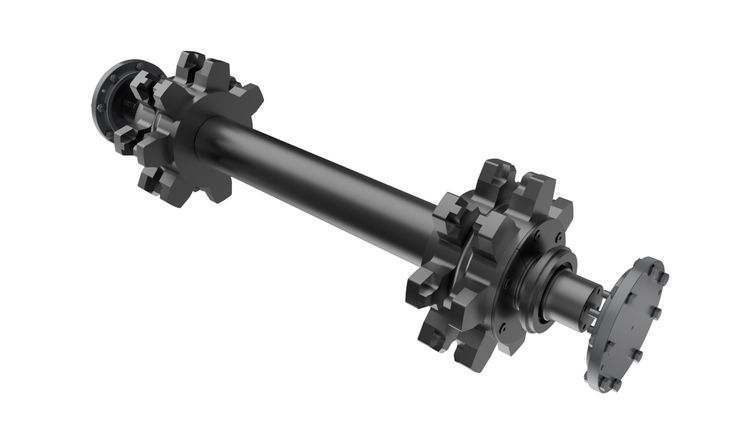

Sprocket & Shafts Assembly

The Head/Tail Shafts are designed for disassembling maintenance as a whole unit. Shafts designed with alloy hardened, tempered and stress relieved steel. Sprockets are designed with either sheet flame hardened steel or split steel to provide additionalmaintenance options.

Tension Device

There is a hydraulic adjustment device at the tail of conveyorbody, and the manual hydraulic pump adjustment device canrealize that even if the feeding end of the machine is buried inthe "material", it can also quickly adjust the chain tightness to ensure the equipment stable operation.

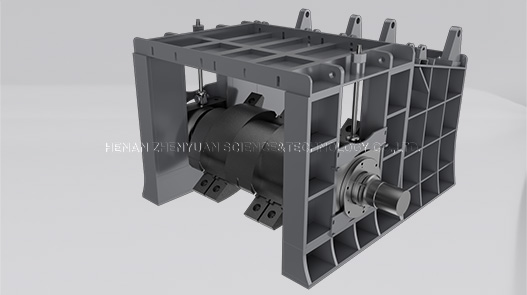

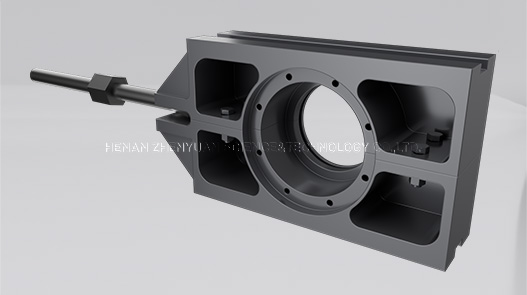

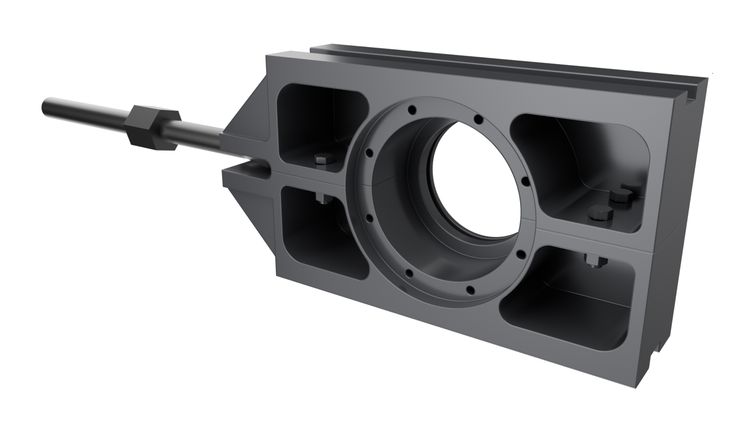

Feeder Box

The Feeder box consists of a number of small feeder boxes connected by high-strength bolts in a row, the main function to connect the head and tail and carry the feeder chain sliding in it to transport materials.

The feeder box is welded by high strength wear-resistant steel plate, strong structure and beautiful appearance. The inner liner plate is made of wear-resistant plate and connected by bolts,making it easy to replace.

FEATURES

Low Investment

No need expensive primary crushers, little or no foundation works required, reduce investment costs. It can be directly fed by the truck or loader, does not require any other specific expensive equipment, greatly reducing equipment cost.

Improve Economic Performance

Feeder Breaker can choose the grate bars or roller screen to achieve the pre-screening function, minimize the powder materials, improve the proportion of finished materials, in order to improve economic benefits and value.

Adjustable Throughput

Equipped with a frequency converter, it can change the speed of the frequency converter motor, thereby changing the running speed of the feeder chain plate, which can achieve the purpose of adjusting the handling capacity of the feeder breaker.

Easy Maintenance

The modular component design allows easy replacement of spare parts, making maintenance easy, reducing costly downtime and saving operating costs.

Automatic Lubrication System

Feeder breaker adopts a centralized automatic lubrication system, which can be remotely controlled.

The automatic lubrication system can set the oil filling interval, the number of oil filling and the amount of oil filling to ensure the effective and reliable lubrication of the core components.

The automatic lubrication system can supply oil with high pressure and fast speed, and it can be monitored remotely, so that the core components can realize good lubrication, which greatly prolongs the service life of the feeder breaker.